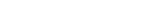

Machining Services

- CNC turning to 36” (914mm) diameter

- Shafts to max length of 160” (4,064mm)

- Cylindrical & taper boring to AGMA & ISO standards

- Inch, metric, & taper keyways to 2.5” (63mm)

- Boring for taper-lock and QD bushings

- Drilling & tapping

- Vertical & horizontal milling

- Sawing to 16” (406mm) diameter

- CMM inspection 28” x 24” x 18”

- CAD/CAM drawing portability

- Demagnetization

- Parts assembly

- Packaging & labeling

- Pick up & delivery

- Rough component stock consignment

Local Partner Sourcing Services

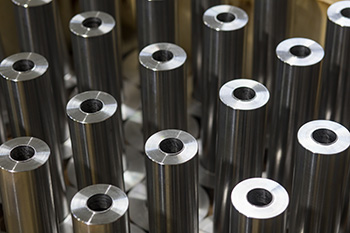

- Splines

- Plating

- Welding

- Precision grinding

- Balancing

Milling

- Bridgeport vertical mill

- Lagun vertical mill

- Acer vertical mill (2)

Key Cutting

LaPointe Machine Broach

- To 5/8” U.S.

- To 14mm metric

LaPointe Machine Broach

- To 1” U.S.

- To 25.4mm metric

Morrison Keyseater

- To 1-1/4” U.S.

- To 32mm metric

- 9” stroke

Mitts & Merrill K-1212

- To 1-1/4” U.S.

- 12” stroke

Mitts & Merrill K-2024

- To 2” U.S.

- 24” stroke

|

|

|

|

|

|

|

|

|

|

Miscellaneous Capabilities

- Daito horizontal band saw - capacity 16” round

- Vertical band saw

- Electro-Arc model 2SAT tap disintegrator

Material Handling Equipment

- GMC pick-up trucks

- HD Ford pick-up truck

Assembly

- General assembly

- Packaging & labeling

|

|

Inspection & Quality

We follow ISO 9001 standard procedures to provide our customers with high-quality machined parts consistently. Our climate-controlled quality lab utilizes coordinate measuring equipment, calibrated inspection gages, and experienced quality control personnel to ensure product quality and verification for our customers.

Inspection Equipment

Mitutoyo BH706 coordinate measuring machine

- Cube x=28” y=24” z=18”

Dial Bore gages (to 8”) with reference rings

- Comptor plug gages w/ reference rings

- Gages to meet customers' needs