Our Equipment

Parameters Industries, Inc. encompasses a well-maintained, 24,500 sq. ft. manufacturing facility.

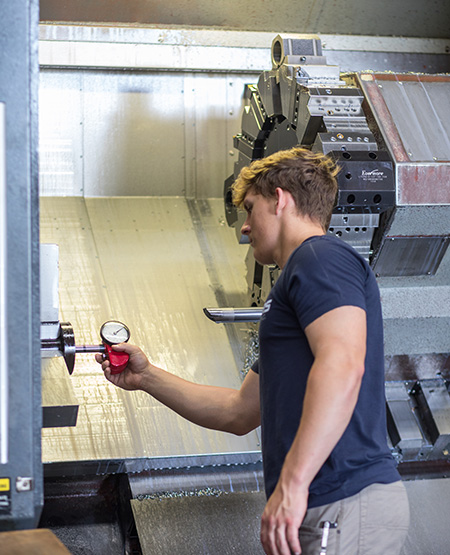

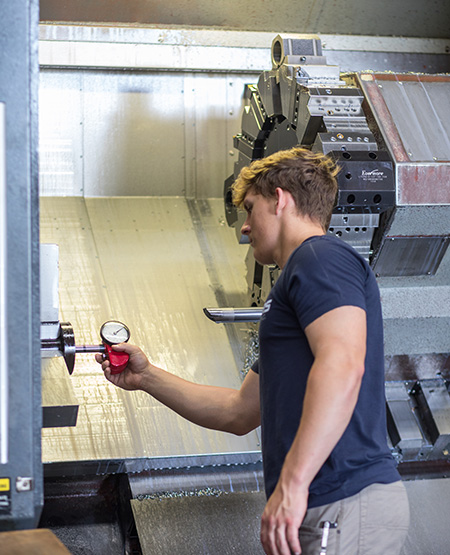

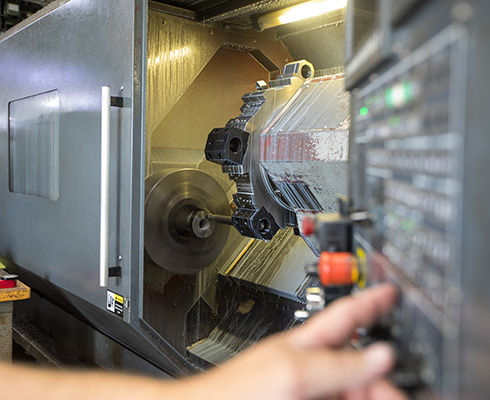

CNC Turning

Turning

|

|

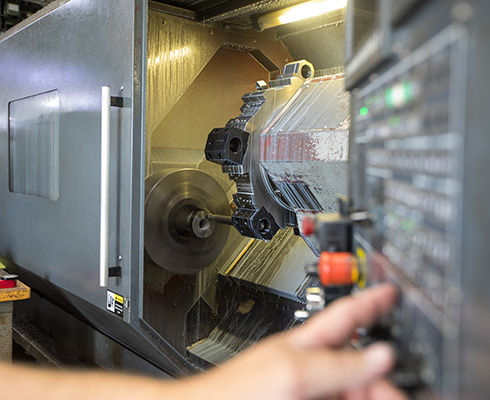

CNC Machining Centers

|

|

|

|

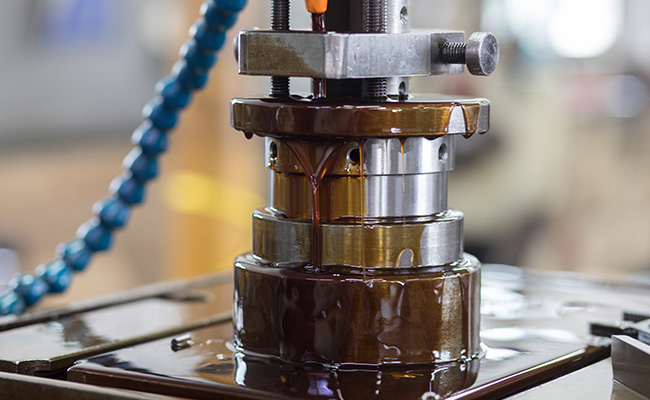

Grinding

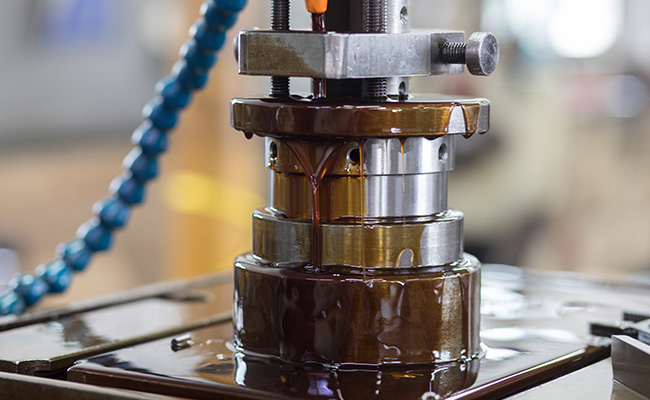

Drilling / Tapping

|

|

Call Us Today! 262.549.3448

Parameters Industries, Inc. encompasses a well-maintained, 24,500 sq. ft. manufacturing facility.

CNC Turning

Turning

|

|

CNC Machining Centers

|

|

|

|

Grinding

Drilling / Tapping

|

|